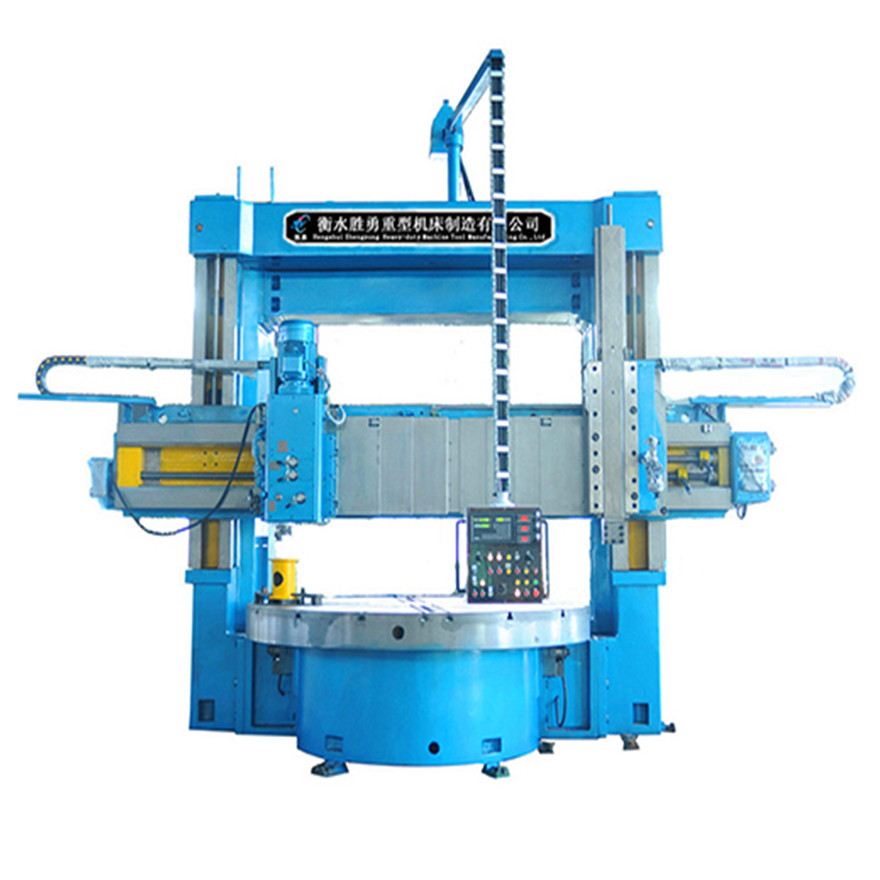

Heavy duty cnc lathes can be divided into single column and double column Vertical Lathes. The difference between single column and double column vertical lathes is that the double-column vertical lathes is equipped with gantry structure. While single column vertical lathes only has one column and one vertical turret usually.

Double column vertical lathes are widely used in metallurgy, machinery, chemical machinery.The Vertical Lathe Machine has large power, good rigidity and high precision. Vertical lathes are suitable for cast iron, steel and non-ferrous metal parts for rough and fine processing.This series heavy duty cnc lathe of vertical Lathe Machine is suitable for the processing of disc-shaped parts such as tire mold, slewing ring, turbine wheel and flange etc.

Double column vertical lathes C5232 belongs to heavy duty cnc lathes,the vertical type heavy duty lathe can be used for rough processing the workpiece of the cylindrical, bore, end and inside and outside the cone and other processing.In addition to the turning function of all ordinary vertical lathes, the vertical type heavy duty cnc lathes also have the functions of constant linear speed turning and thread threading.

Heavy duty lathe base is an integral high rigidity cast iron structure with reasonable cutting space.The column is closed with gantry frame, and the structure size and stress state are optimized by finite element analysis.Heavy duty cnc lathe CNC system using Siemens, Fanuc or by the user to select other systems. The main motor can use AC servo motor, you can also use AC variable frequency motor.

Technical parameters of Double column heavy duty vertical lathes C5232

Table diameter:Φ2830mm

Maximum turning diameter:Φ3200mm

Maximum height of workpiece:1600-3000mm

Maximum weight of workpiece:10/20/32ton

Maximum cutting torque of table:63000N.m

Step of table rotation:16 step/ Two gears stepless speed regulation

Speed range of table:2-63r/min

Feed step :18 step/ Stepless speed regulation

Range of feed rates :0.25-90/0.1-1000 mm/min

Rapid travelling speed of tool post :1550/2000mm/min

Beam travel:1250 mm

Horizontal travel of tool post:1750mm

Vertical travel of tool post:1000/1250/1400/1600 mm

Beam lifting speed:350mm/min

Maximum rotation angle of tool post:±30°

Clamping size of tool chuck ( Width X Height):40×50 mm

Power of main motor:55 KW

Overall dimensions (L×W×H ):5880×4600×4952mm

Machine weight ( approx ):36-50ton

More heavy duty cnc lathes in factory

Product Categories : Lathe Machine