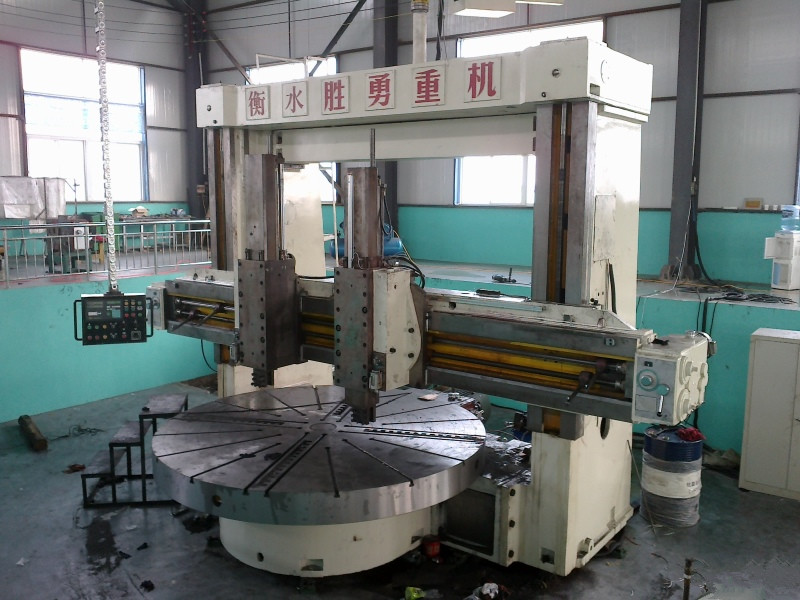

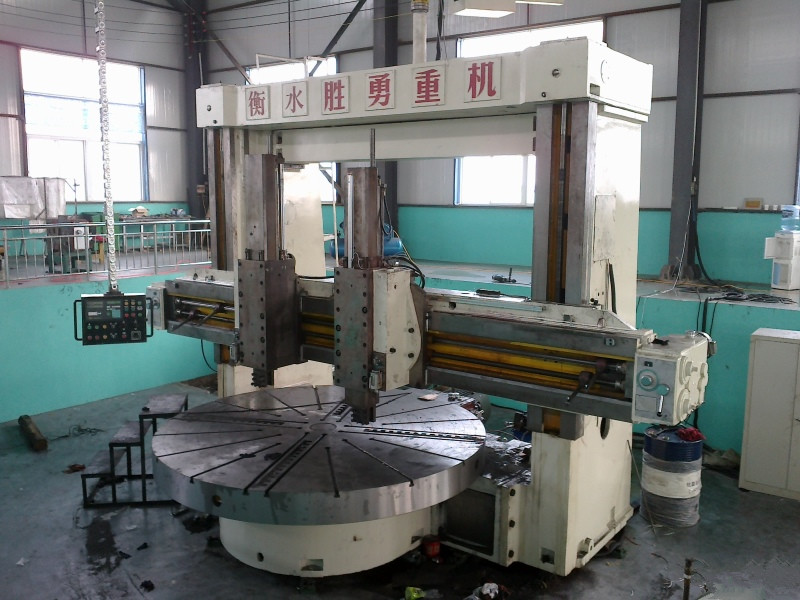

CNC vertical turning machining lathe is a wide range of applications, high production efficiency of advanced equipment. CNC vertical machining is two-axis linkage movement mainly processing arc surface, cylinder-shaped surface and circular conical surfaces. Beds of cnc vertical machining are made of resin sand casting, good stability, high strength. Through two aging treatment to eliminate stress, ensuring long-term stability. Grade 16 machinery variable speed makes the device convenient, improving maximum torque output and making cnc vertical turning can adapt to the overloaded power cutting.

CNC Vertical Lathes can efficiently and automatically process kinds of ferrous metals and alloys, non-ferrous metals, non-metallic materials.Vertical Lathe Machine is suitable for single piece and batch processing of revolving parts in various industries.Vertical Lathe Machine is widely used in machinery manufacturing and mechanical repair departments. CNC Vertical Lathes are suitable for motor, turbine, aviation, mining machinery, metallurgy and general machinery industry.

CNC vertical machining can also be provided with DRO equipment, grinding function, cooling and chip removal components based on user requirements.CNC Vertical Turning Lathe can finish end face, inside and outside cylindrical surface, inner and outer conical surface and slot processes.

Technical specification of CNC vertical turning lathe machining CK5126

1 Table diameter 2300mm

2 Maximum turning diameter 2600mm

3 Maximum Height of workpiece 1300mm

4 Maximum Weight of workpiece 10 t

5 Speed range of table 2.5-80 r/min

6 rotation speed of work table 16

7 Range of feed rates 0-1000 mm/min

8 Step stepless

9 horizontal travel of vertical slide 1600 mm

Vertical travel of vertical slide 915 mm

10 Horizontal travel of side tool post 750 mm

Vertical travel of side tool post 900 mm

11 Crossrail travel 850 mm

12 Maximum size of tool bar section 35×45 mm

13 Power of main motor 37 kw

Rotating Speed 1470r/min

14 Power of feed motor 1.3/1.7 kw

Rotating Speed 940/1440 r/min

15 Rapid travelling speed of tool post 2000 mm/min

16 Machine weight(Approx) 19.5 t

17 Overall dimensions(L ×W×H) 3450x3430x4100mm

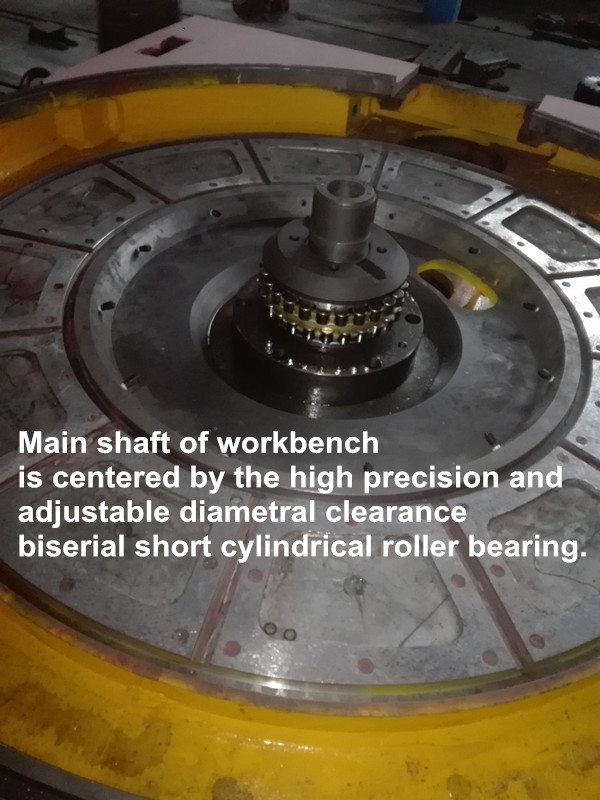

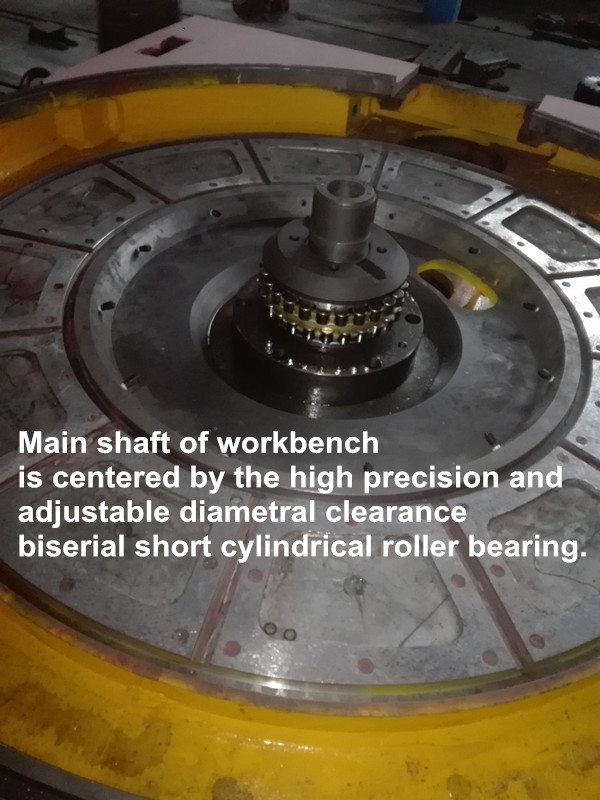

Parts of CNC vertical turning lathe machining

Recommend CNC vertical turning lathe machining

Product Categories : Lathe Machine